Platinum in catalytic systems, catalyst grids

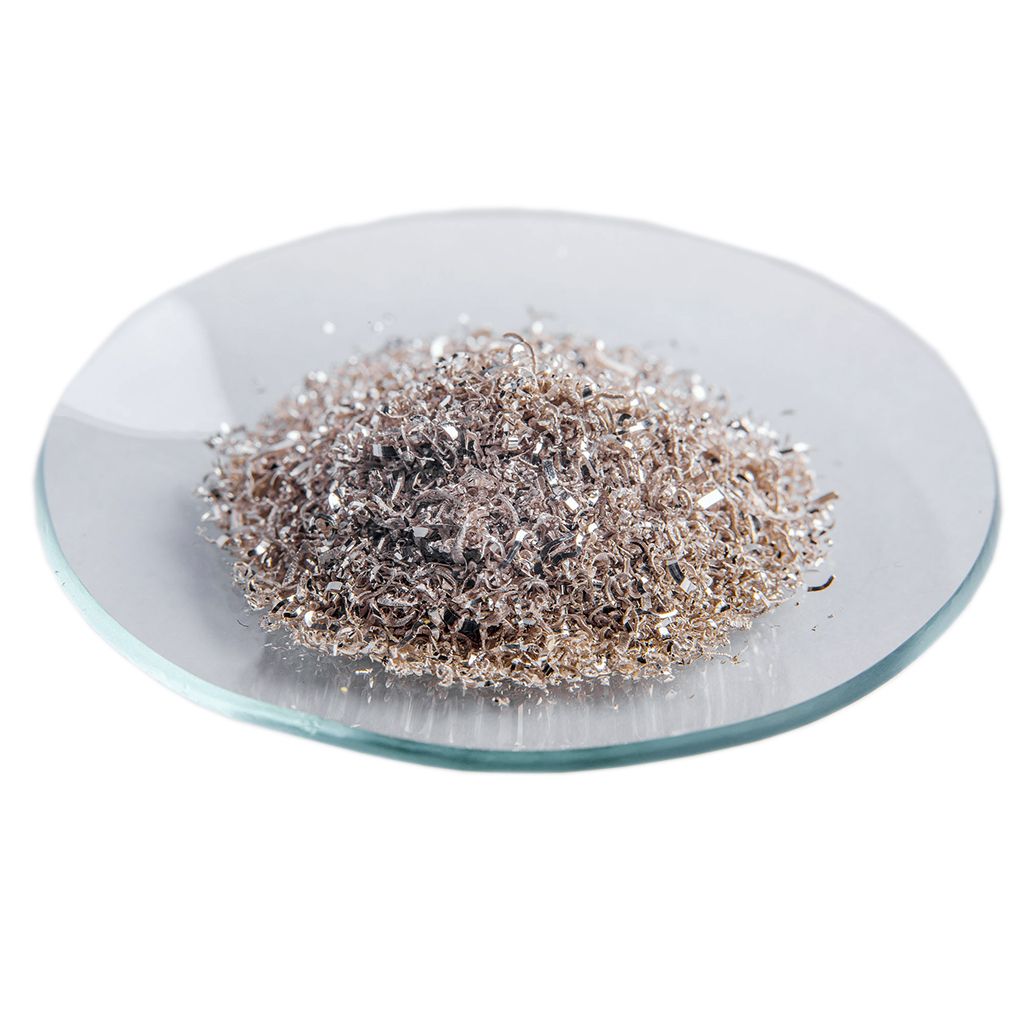

Product description

Detailed description

The catalytic system in the traditional design consists of a grid package with a diameter of 0.5 to 6.0 meters, made of alloys containing different ratios of precious metals depending on the application, metal separation grids with a wire diameter of 60 to 400 microns and includes: catalyst grids made of platinum-based alloys; catalyst grids applied with an active coating; trapping grids made of palladium alloys; separation grids.

Catalyst meshes can be made of two types: knitted and woven

Knitted - alloy: PlRd-5, PlPdRd-16-3, PlPdRd-37-3, PlPdRd-4-3.5 wire diameter: 0.076 - 0.094

Woven - Alloy: PlRd-7.5, PlPdRd-16-3, PlPdRd-4-3.5; wire diameter: 0.076 - 1.00

The trapping grids have a woven structure and are installed after the catalyst grids. These grids are designed to capture platinum and rhodium during operation. The use of trapping grids makes it possible to reduce the investment of platinum and rhodium in catalyst grids, as well as reduce the specific losses of precious metals.

The separation grids have a woven structure, are installed between the trapping grids and prevent palladium entrainment.

Catalyst meshes with an active coating: Main characteristics: woven meshes with a wire diameter of 0.2–0.25 mm; active coating based on platinum and other elements; active ingredient content 0.3–0.4% by weight; base of fechral wire.

Specifications

- that

Interested in this product?

Contact us for detailed information and to place an order